Electrical Wire Color Code Charts⁚ A Comprehensive Guide

This guide provides a comprehensive overview of electrical wire color codes, including international (IEC 60446) and North American (NEC) standards. We will explore various color combinations and their meanings for different wire types, along with troubleshooting tips and safety precautions. PDF resources are also highlighted for further reference.

Introduction to Wire Color Codes

Standardized wire color codes are crucial for electrical safety and efficient installation. These codes visually identify the function of each wire within a circuit, preventing misconnections and potential hazards. Different regions and standards bodies, such as the International Electrotechnical Commission (IEC) and the National Electrical Code (NEC) in North America, define specific color schemes. Understanding these codes is essential for electricians, engineers, and anyone working with electrical systems. Incorrect wiring can lead to electrical shocks, fires, and equipment malfunctions. This guide aims to clarify common color codes and their regional variations, helping to ensure safe and correct installation practices.

The use of color codes simplifies complex wiring diagrams, making troubleshooting and maintenance easier. By quickly identifying hot, neutral, and ground wires, technicians can work more efficiently and safely. Consistent adherence to these codes is a fundamental principle of electrical safety regulations worldwide. The information provided here is for educational purposes and should not be considered a substitute for professional electrical advice. Always consult relevant codes and standards for your specific region and application.

International Standards⁚ IEC 60446

The International Electrotechnical Commission (IEC) standard IEC 60446 is widely adopted globally for electrical wiring color codes. This standard provides a consistent framework for identifying the function of wires in electrical installations, enhancing safety and facilitating international collaboration in electrical projects. Unlike regional standards, IEC 60446 aims for universal understanding, reducing the risk of misinterpretations and errors during installation and maintenance.

Key color assignments under IEC 60446 typically include brown for the active (hot) conductor, light blue for the neutral conductor, and green-yellow for the protective earth (ground) conductor. However, specific color assignments can vary depending on the number of phases and the application. Variations might exist for secondary conductors or in specific industrial settings. Always refer to the complete standard and local regulations for detailed guidance. The UK, for instance, has adopted IEC 60446, aligning its wiring practices with this international standard. This harmonization improves safety and interoperability within the global electrical industry.

While IEC 60446 promotes consistency, it’s crucial to remember that regional variations and exceptions might still exist. Always verify the specific color codes used in a particular installation to avoid potential misinterpretations. Understanding the nuances of this standard is key to safe and efficient electrical work.

North American Standards⁚ NEC

The National Electrical Code (NEC), a widely recognized standard in North America, defines color codes for electrical wiring. Unlike the internationally standardized IEC 60446, the NEC offers slightly different color conventions. While the NEC does allow for some flexibility, it strongly recommends specific colors for different wire functions to ensure clarity and safety. This helps electricians and other professionals quickly identify the purpose of each wire, minimizing the risk of electrical hazards.

In typical residential and commercial installations following NEC guidelines, black is the standard color for hot wires, carrying the main electrical current. Red is often used for secondary hot wires in multi-wire branch circuits. White, on the other hand, signifies the neutral wire, which carries the return current. Bare copper or green-coated wires are universally reserved for the grounding wire, providing an essential safety path for fault currents. Proper grounding is crucial for protecting equipment and people from electrical shocks.

It is important to note that while these are the commonly used colors, exceptions exist. For instance, in some specific applications or older installations, different color codes may be encountered. Always refer to the applicable NEC standards and local regulations for precise specifications within a given installation to ensure compliance and safety. Consulting the complete NEC documentation is essential for proper interpretation and application of these standards.

Understanding Ground Wires

Ground wires, a critical component of any electrical system, play a vital role in safety and proper operation. Their primary function is to provide a low-resistance path for fault currents to flow back to the source, preventing dangerous voltage buildup and protecting against electrical shocks. This is achieved by connecting exposed metal parts of equipment and wiring to the earth, effectively diverting any stray current away from humans and sensitive electronics. The color coding of ground wires is standardized across various electrical codes to easily identify them.

Commonly, ground wires are identified by a distinctive green or green-with-yellow-stripe color. This visually distinct marking helps electricians and other personnel quickly recognize and differentiate them from hot and neutral wires. In some instances, bare (uninsulated) copper wires might also serve as ground conductors. This color convention provides a crucial visual cue, significantly reducing the risk of accidental contact with potentially hazardous voltages. The use of consistent coloring is a vital safety measure in electrical installations.

Proper grounding is essential for preventing electrical hazards and ensuring the reliable operation of electrical equipment. Failure to correctly ground a system can lead to severe consequences, including electrical shocks, equipment damage, and even fires. Therefore, understanding the role and identification of ground wires is paramount for electricians and anyone working with electrical systems. Always prioritize safety and adhere to relevant electrical codes when working with electrical wiring.

Common Wire Colors and Their Meanings

Standardized wire color codes are essential for electrical safety and efficient troubleshooting. These codes, while varying slightly by region and application, generally follow established conventions to quickly identify the purpose of each wire. Understanding these color codes is crucial for electricians and anyone working with electrical systems. The most common color codes represent hot, neutral, and ground wires.

Hot wires, carrying the main electrical current, are often black, red, or blue, with the specific color sometimes indicating different phases in multi-phase systems. The neutral wire, which completes the circuit and carries current back to the source, is typically white or gray. Ground wires, providing a safety path for fault currents, are almost universally green or green with a yellow stripe, or may be bare copper.

However, it is crucial to remember that these are general guidelines. Regional variations exist, and specific applications may utilize different color schemes. Always consult the relevant electrical code and any accompanying documentation for the specific system being worked on to ensure accurate identification and avoid potential hazards. Misinterpreting wire colors can lead to serious safety issues.

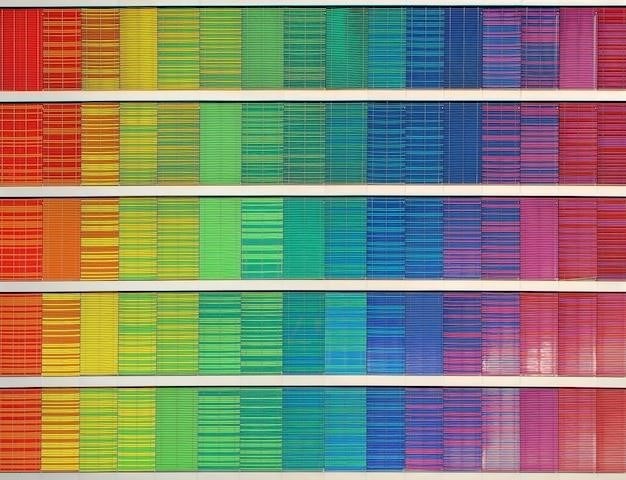

Color Codes for Different Wire Types

While the basic hot, neutral, and ground color scheme provides a foundation, variations exist depending on the specific type of wire and its application. For instance, control wires, often used in lower-voltage circuits for signaling or switching, might employ a wider range of colors beyond the standard three. These colors are often chosen to distinguish between different control functions within a system. These control wires might be found in industrial settings, HVAC systems, or even complex home automation setups.

Similarly, fiber optic cables, used for high-speed data transmission, utilize a distinct color-coding scheme. This scheme often involves a sequence of colors, sometimes incorporating stripes or combinations, to identify individual fibers within a bundle, allowing for easy tracing and connectivity. This system differs significantly from the standard electrical wiring color codes.

Furthermore, some specialized cables, like those for high-voltage applications or industrial machinery, may deviate from standard color conventions due to specific safety requirements or industry practices. Always refer to the manufacturer’s specifications for these less common cable types to avoid misinterpretations and ensure safe operation.

Troubleshooting and Safety Precautions

Accurate wire identification is crucial for safe electrical work. Misinterpreting color codes can lead to dangerous electrical shocks or equipment damage. Always verify wire functions using a voltage tester before working on any circuit, regardless of the apparent color-coding. Never assume a wire’s purpose based solely on its color; consult wiring diagrams and schematics whenever possible.

When troubleshooting, systematically check each wire’s continuity and voltage using appropriate testing equipment. A multimeter is an essential tool for verifying wire integrity and identifying voltage levels. Remember to always disconnect power to the circuit before performing any physical work on wires or electrical components. Improper handling can cause short circuits, fires, or severe injury.

If you’re unfamiliar with electrical wiring, seek professional assistance. Attempting complex repairs without proper knowledge and training poses a significant risk. Consult qualified electricians for installations, repairs, and troubleshooting of electrical systems to ensure safety and compliance with local building codes. Proper training is essential for safe handling of electrical equipment.

Color Codes in Specific Applications

Beyond general wiring, specific applications utilize unique color-coding schemes. For instance, telephone cables often employ a complex system of paired colors, sometimes including stripes, to distinguish individual lines within a multi-conductor cable. This allows for easy identification and connection of individual circuits within a larger system, critical for efficient communication networks. Fiber optic cables also utilize color-coding for identification purposes, often following a standardized sequence for various fibers.

In industrial settings, control panels frequently use color-coded wires to manage complex circuits and signals. These color schemes can be customized based on the specific system requirements but generally adhere to established standards for clarity and maintainability. This is especially important for complex industrial machinery, where easy identification of wires is vital for troubleshooting and maintenance.

Automotive wiring harnesses also employ specialized color codes. These codes help technicians quickly identify wires responsible for specific functions, such as power, sensors, or ground connections, streamlining repair processes and ensuring correct function. Consult a wiring diagram specific to the vehicle in question for accurate identification.

Regional Variations in Color Codes

While international standards like IEC 60446 strive for uniformity, regional variations in electrical wire color codes persist. These discrepancies can stem from historical practices, national regulations, or industry-specific conventions. For example, while many countries adhere to the IEC standard, the United Kingdom, initially using a different system, has gradually transitioned to align with IEC 60446. This transition demonstrates the ongoing evolution of color-coding practices.

North America, primarily using the National Electrical Code (NEC), maintains a distinct color-coding system compared to the IEC standard. This difference necessitates careful consideration when working with electrical systems from various regions. Understanding these differences is crucial for electricians and technicians to prevent errors and ensure safety. Misinterpreting color codes can lead to malfunctions or even hazardous situations.

Other regions may exhibit further variations. Some countries might use color combinations not found in major standards. Therefore, always consult local electrical codes and regulations to ensure compliance with the relevant standards for a given location. Ignoring regional variations can be dangerous and lead to non-compliant installations.

Finding and Using PDF Resources

Numerous websites and organizations offer downloadable PDF resources detailing electrical wire color codes. These PDFs often provide comprehensive charts illustrating various color combinations and their corresponding meanings, greatly aiding in identification and understanding. Searching online using keywords like “electrical wire color code chart PDF,” “wiring color codes PDF,” or “IEC 60446 PDF” will yield many results.

When using these PDFs, it’s crucial to verify the source’s reliability and ensure the information aligns with current standards and regulations in your specific region. Outdated or inaccurate charts can lead to dangerous misinterpretations. Look for PDFs from reputable organizations like national electrical codes bodies or established electrical engineering associations. Many manufacturers also publish PDF guides specific to their products.

Once you’ve located a reliable PDF, carefully review the chart’s legend to understand the symbols and abbreviations used. Pay close attention to any notes or qualifiers that might clarify exceptions or special cases. Print a copy for easy reference during electrical work. Remember that proper identification is crucial for safe and efficient electrical installations and repairs.

Resources and Further Reading

For a deeper understanding of electrical wire color codes and related safety practices, several resources are available beyond the basic charts. National Electrical Code (NEC) publications provide detailed information on standards and regulations specific to North America. The International Electrotechnical Commission (IEC) website offers international standards like IEC 60446, which governs color coding in many parts of the world. These official sources are invaluable for accurate and up-to-date information.

Many online forums and communities dedicated to electrical work offer discussions and insights from experienced electricians and engineers. These platforms can be helpful for clarifying specific questions or resolving unusual situations not covered in standard documentation. Always prioritize information from verified and reputable sources to avoid misinformation.

Educational websites and online textbooks covering electrical engineering fundamentals often include sections on wire color codes and their significance within larger electrical systems. These resources may offer a more comprehensive context and explain the rationale behind color-coding practices. Supplementing PDF charts with these broader learning materials can enhance your overall understanding and improve electrical safety practices.